|

We see or experience centrifugal force and

inertia every day of our lives, and intuitively know how it works. One of the

best examples is twirling a rope with a weight on the end. We know the faster

and further out the weight is, and the heavier the weight, the further the

weight will fly when we let go. This is because we store more energy in the

weight as we move it faster, swing it in a wider circle, or use a heavier

weight. The energy isn't really wasted, it is stored and released later.

Common Questions

There are several

common questions

about rotating mass.

A few

of them are:

If I use a lighter

crankshaft, how much

power is gained?

If cluster gear

weight of a

transmission is

reduced, how much

will acceleration

improve?

How much will a

light-weight

aluminum flywheel

improve

acceleration?

How much ET can be

gained from using lighter wheels?

Does an aluminum driveshaft speed up my car?

These

questions can be

answered if we know

the weight change,

the distance out

from the center the

weight change occurs

at, the speed (RPM),

and the time period

over which the RPM

change occurs. Even without exact calculations, we can get a feel for how things

change. This will help us budget our money and make better choices, or at least

have a feeling for what we are accomplishing.

Using readily available

on-line calculators, we can

understand how changes in rotating mass will affect available horsepower in a

vehicle.

What does a rotating

mass actually do?

A rotating mass

does not really

consume or dissipate energy. A rotating

mass stores energy. The rotating mass

eventually either returns energy to

the system in a useful way, or

something converts the stored energy to some

other form of unwanted energy. The conversion might be with a friction,

converting to heat. The

energy stored might

be helpful, like the smoothing of cylinder pulses in an engine flywheel. The

energy stored also might not do

anything at all, or the stored energy

can even be harmful, reducing acceleration or braking.

Accelerating an unnecessary rotating mass requires energy, and

the acceleration process saps some of the horsepower we have available to

accelerate our vehicles. Reducing

available horsepower affects acceleration in a very predictable manner, and the

horsepower amount needed to spin something up gives us some feel for how important a part change might be.

Four things

determine the effect

of rotating mass. Every one

of these things is important:

-

How quickly and

often a

rotating mass

speeds up or slows

down. Every time it is forced to speed up or slow down, it takes or releases

energy

-

How heavy the

rotating mass is. More weight (with no other changes) stores or releases more

energy

-

The rotating

weight's distance

outwards from the

centerline. The further out, the more energy pushed in and out of a given

weight

-

How fast the weight

spins, or the speed the weight travels in a given circle diameter. The higher

the RPM, the more energy stored

Here are how these things work:

- If we push energy

into the rotating

mass and pull

energy out several

times, we move more power

around than if we

make a slow, smooth,

change in speed. It takes much more effort to repeatedly speed and slow

something in a short period of time than to gradually speed it or slow it

- The amount of weight is the least important

thing! If we double the weight (with no other changes) we only double the

stored energy

- Weight distance

from the center

line is very

important, because

it determines the

weight's circular velocity

(speed)! Stored

energy goes up by

the SQUARE of the

radius change. If

we replace a 4-inch

diameter hollow

driveshaft with an

8-inch

diameter tube of

exactly the same weight,

it is not just double. It is twice the size squared, or four times

the stored energy when it weighs the same!

- The faster we spin the weight, the more energy it stores. If we double

RPM, we

multiply stored

energy four times.

Again it is a

square of the

change, just like

weight distance from centerline is a

square.

The above is very important. If

we double the effective "circle size" the weight is rotating at, we get

four times the stored energy. If we simply double the weight without

changing the spinning radius, we just double stored energy:

- If we reduce

mass from twenty

pounds to ten pounds,

keeping the same distance

out and same peak RPM, we

reduce stored

energy to half the

original amount.

Reducing weight is a

one-for-one change.

- If we cut diameter in half while

keeping the same weight

and RPM, stored energy

will be 1/4 the original

stored energy. This

change is a square.

Twice is a "four times"

effect. 2*2=4. Four

times is a sixteen

time effect on

stored energy.

4*4=16

- If we cut

RPM in half, we

would reduce stored

energy to 1/4 the

original amount.

Once again this is a

squared change.

Change RPM three

times, and the

stored energy

changes nine times.

3*3=9

We should

carefully think

about what this

means when we

change things.

Some changes are

worthwhile, some are

not. We also cannot use carte blanche rules, like the silly rumor that reducing

a rotating weight is like dropping the vehicle weight four times that amount. As

a matter of fact, it is probably never four times. It is more likely closer to

one, and might even be less than one!

Wheel Changes

Let's assume, just as an example, all

of a wheel's weight is at the

outer edge and

remains at the outer

edge. If

we reduce a wheel's

diameter but keep

the overall weight

the same, the wheel

is a spinning ring

with smaller

diameter. The

smaller diameter

increases the wheel's RPM at

the same vehicle speed.

The smaller diameter

also moves the

spinning weight

closer to the

center.

Let's say we cut

diameter in half.

Now think about how fast the

wheel spins. RPM

will be twice

what it was at the

same speed. The

half size diameter

reduction spins the

wheel twice as fast,

and that would

increase stored

energy to four times the

original amount if

the weight was the

same distance out. But the weight isn't the

same distance out.

The spinning weight

is now half size.

This 1/2 size

reduction decreases

stored energy by

four times!

If we did not change the weight or weight

distribution, and we reduced a wheel and tire diameter by half but drove the

same speed, nothing would change. It would be a major change that just broke even. Moving the

weight closer to

the rotation center reduced stored energy, but the increased RPM to maintain the same speed

increased stored energy the same amount.

One cancelled the other, and stored energy did

not change!

If we change tire and wheel diameter without

changing weight distribution and weight in the tire and wheel, we don't change a

thing.

In this example, we gained

nothing from a significant physical change.

We

also lost nothing.

Lightening the tire or wheel some distance out from the hub reduces

stored energy. This is especially true if

the weight reduction is far out

from the center. If we change the weight one-pound fourteen inches out, it is

like changing weight four-pounds seven inches out.

Which brings up an

important point we

almost never hear

mentioned, a lower

weight part might

not be lighter at

the outside edge. It

might be lighter in

the center, where

the weight reduction

doesn't mean much.

It is more important to make

something as light

as possible on the

OUTER edge, rather than near

the (wheel) center.

Spending money on

smaller or lighter

rotors to save

rotating weight should be down the list, because the

rotating weight is

closer to the wheel hub. Unless the

rotors are huge and

we take weight out of the

rotor's outer areas, things

will not change much.

(A light rotor and wheel is good for

reducing un-sprung

weight, and that

helps keep

our tires in

contact with the

road. It also

reduces vehicle

weight. But this is a

different problem.

Here we are talking

about rotation, not

the bounce inertia

or "dead weight".)

If we spent money on

the same weight

reduction in the wheel,

reducing weight out

a little further away from the

center, we would do

much better.

We would be removing weight

further out from the

center, where it

does the most good.

If we spent

our money on a

lighter tire we

would be

getting the very most

return for the

weight change. The

tire's weight change

is mostly outside

between the rim edge

and the tread area. We

get maximum effect

from the weight change!

Think about this

carefully. If we buy

a lighter tire, we

know for sure the

weight comes off the

most critical area.

If we buy a lighter

rotor, it is close

to the center and,

for the same weight

change, the return is

much less.

The wheels also

speed up and slow

down gradually. With

an 11-second car, we

have 11-seconds to

speed the wheel up.

Most of the

horsepower pushed

into the wheel and stored is

pushed in near the

end, when

acceleration is

least. Since we have

more time to push

the bigger amount of

energy into the

wheel, it takes less

horsepower than we

might expect.

Drive Shaft Example

Now let's think

about a drive shaft.

The driveshaft is a

fairly thin hollow tube.

Nearly all drive shaft

weight is

at the outside,

since it is (of

course) hollow.

The shaft also turns

at the same RPM no

matter what the

driveshaft diameter, because

the RPM is set by

the rear end ratio, tire

diameter, and

vehicle speed.

If we make a

driveshaft lighter

and keep everything

else the same, the

vehicle acceleration change is

often

insignificant.

Why would it be insignificant in

most cases?

In the

first place, the

drive shaft is small

in diameter. With a

small diameter, less

energy is stored for

a given weight. In

the second place, a

driveshaft is

really not that

heavy. A steel

Mustang driveshaft weighs

somewhere around 30 pounds, so

we just can't take that

much weight out.

Also, the

driveshaft

spins up gradually

and smoothly

over a long period

of time. It

accelerates fastest

at slowest speeds,

and that is when it

needs the least

energy to spin up. Because it

has a long time to

spin up, is a small

diameter, and because it does not weigh much,

the driveshaft does not remove

very much horsepower

at any instant of

time. Despite

what we are told, a change

in driveshaft weight has, at

best, a very

small effect on

acceleration. Likely

any change is

immeasurable in a

street/strip car.

Now a lighter shaft

certainly can help

in a very light

vehicle. It can also help in a road

race car (as will a light crank and flywheel), because road racing requires

instantly changing from acceleration to deceleration.

A light driveshaft won't change

anything significant or measureable in a 3000-pound

11-second car,

except how fast

dollars leave your

wallet!

Another worry is driveshaft diameter. If we go from

a 30-pound 3-inch steel driveshaft to a 30-pound 3.5-inch aluminum shaft, we

move the weight out 3.5/3 = 1.167 times. That increases stored energy 1.167^2

times, or 1.36 times. If we store 0.3 horsepower in the shaft, changing the

diameter will increase that to 0.4 horsepower. We would have to reduce weight

14.3% to 25.7 pounds just to break even with the diameter increase.

The worst thing about a driveshaft is the diameter

is so small, and the acceleration time is so long, there just isn't much

horsepower being sapped from the system. A typical steel driveshaft in a typical

12 or 13 second car only stores an average of about 1/4 horsepower. If we got

100% of that back with a zero weight shaft, we would never notice it.

Good reasons to change a driveshaft are to get rid

of vibration and harmonic resonances in the shaft, to make it stronger, or to

simplify a two-piece driveshaft system. The silliest reason is to speed the car

up. Even if we only pay $100 for a shaft, it would typically be much less than

1/4-horsepower average gain. That would be paying much more than 100/.25 = $400

per horsepower. Paying a lot more than $400 per horsepower is not a good

investment.

Flywheel Change Horsepower

A flywheel can be

fairly heavy, and

the weight is a good

distance out from

the center. It spins

at crankshaft speed,

and it has to abruptly change speed (slow down) at every

up-shift.

While a driveshaft stores around 1/4 horsepower

spread over 12-13 seconds of time, the flywheel is entirely different. The

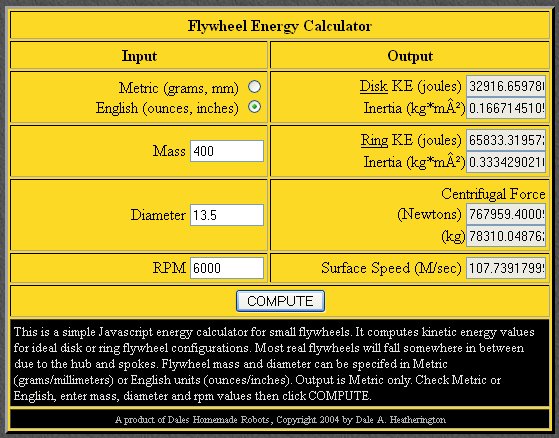

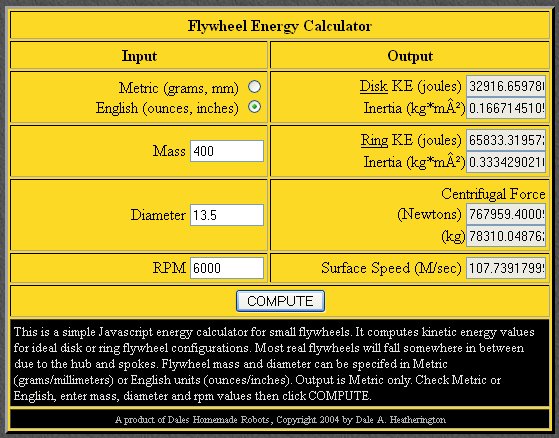

stored energy in a 25-pound 13.5 inch diameter flywheel at 6000 RPM is something

around 32,916 joule-seconds. This is 44.12 horsepower-seconds of power.

Looking at a 13.5 inch diameter 25 pound steel

flywheel at 6000 RPM, we have:

A 25 pound (400 oz) flywheel has

about 32,916 joules of energy. Since each joule is one watt/second, and since

746 watts equal one horsepower, we have 32,916/746 = 44.12 horsepower-seconds

stored. This would be one horsepower applied over 44 seconds, or 88 horsepower

over 1/2-second, to reach 6000 RPM from zero.

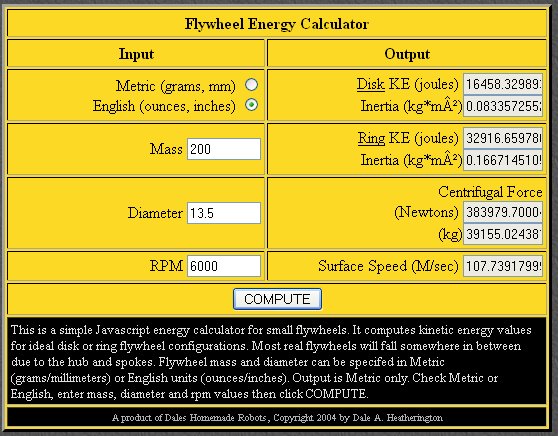

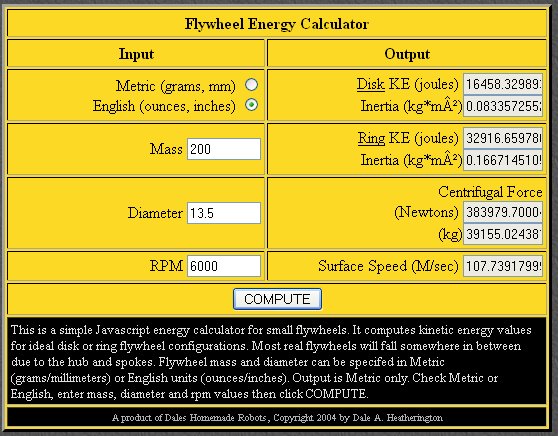

An aluminum 12.5 pound flywheel would have half that

energy, because weight is a direct one-for-one change in energy. If we ran it on

a calculator we would see:

This is about 16,485 joules, or 22

horsepower-seconds of power. Before we run off thinking we will gain 22

horsepower by swapping flywheels, we have to realize this is horsepower-seconds

. Also, the flywheel is NOT starting from zero speed!

If we launch our car at 4000 RPM, the flywheel

starts at 44.4% of the 6000 RPM energy. (square of 4000/6000 times 6K RPM power)

This is 19.6 horsepower-seconds with a steel wheel, and 9.8 horsepower-seconds

with an aluminum wheel, of initial launch stored energy. We only have to add 12

horsepower-seconds to the aluminum wheel, and 24 horsepower-seconds with the

steel wheel.

If we have two seconds to spin up to 6000, the

engine will push either 6 horsepower average with aluminum, or 12 horsepower

average with steel, into the flywheel. If we have 6 seconds to spool up, average

horsepower is either 2 or 4 horsepower.

Also, not all of that stored energy is wasted. When

we shift to second gear, the extra energy is returned on the shift. The engine

gets a "boost" as the flywheel power is returned to the slower-turning

transmission input shaft.

A car with street tires and traction issues will

benefit from a heavier flywheel on launch, and be hurt more on the shift.

A car with good traction will benefit on the launch

with the heavier wheel, but could loose a little power as it runs up through low

gear.

Either way, we are not talking much power, and the

results are highly dependent on the vehicle. We might gain ET or lose ET

depending on many factors.

There are two general ways the flywheel affects

acceleration, although this can vary. In a

light car with very

fast 60-foot times,

a lighter wheel can

slightly improve

60-foot times. This

is because the

launch is often at

full throttle, the

car generally has a

steep gear, and we

want to plant the

tires hard into the

track without

encouraging spin.

The tires hook hard,

and usually have a

very soft sidewall

that absorbs shock.

We want the engine

to quickly match the

RPM needed to move

the rear wheels, and

not overpower the

available traction.

It is a wide open

throttle high-RPM

launch.

A typical

street-strip car is

different. Generally

we can't launch at

wide open throttle,

the tires are

stiffer walled, the

suspension is

heavier, and things

just don't hit as

hard. We actually

want a heavy wheel

(and a heavy crank)

to smooth out the

power. This lets us

have a much more

controlled launch,

and smoothes out any

sudden application

of throttle. An

aluminum wheel,

especially when the

car is severely

traction limited and

heavy, can really

hurt 60-foot times.

A light aluminum

wheel not only makes

a street car hard to

drive, it usually hurts at

the track. It is

especially bad with

a heavy street

machine.

Now that we have seen the flywheel in detail, we can

compare it to the driveshaft. The flywheel is typically around 20-40

horsepower-seconds of energy, and has a somewhat small effect on overall power.

The driveshaft has about 5.5 horsepower-seconds of energy, and has the full

length of the track to spin up.

In a 13 second car, the driveshaft consumes about

1.5 horsepower maximum over the first sixty feet. If we cut the driveshaft

weight in half with no increase in diameter, we would pick up 0.75 horsepower.

If we increase diameter from 3 to 3.5 inches and reduce weight by 30%, we would

just barely change the driveshaft's stored energy. The added diameter would

increase stored energy 1.36 times, and the reduced weight would reduce stored

energy by 30%. We would gain about 0.25 horsepower-seconds, or 0.02 horsepower

average power gain over the track length with a 13 second car.

Crankshaft

A crankshaft is a

bit worse than

a drive shaft.

A crankshaft

accelerates and

changes speeds through

every gear, so it is

constantly storing

and returning energy

to the system. In

low gears it spins

up pretty fast,

spinning up from

"launch" RPM to

shift RPM. This

spin up repeats at

every shift. The

crank also

has to be heavy to

support the pounding

and tugging of the

pistons and rods as

they accelerate and

decelerate, so we

are dealing with

some weight.

Fortunately the

crank diameter is

small. A 3-inch stroke

requires only a 1.5-inch throw radius. Unless we make a

huge change in

OUTSIDE weight in

the counterweights,

in most engines making the crank lighter

makes very little sense. The

dumbest thing to do

is hollow out the

crankshaft center

because it is the

smallest rotating diameter

area. Don't believe

this?

Download the

following technical

paper from the

Scat Crankshaft

website.

Lightweight

Crankshafts-

Performance or

Deception

Scat has it 100%

correct. Many bench

racers, and even

some crankshaft

manufacturers,

exaggerate a good

bit! They

remove weight where

it makes little

difference in stored

energy, but might

make a difference in

strength. Some

transmission experts

worry about the

wrong thing also. If

we worry about the

outside edge weight

of the largest-diameter fastest-spinning parts that

speed up and slow

down at every shift,

we are worrying

about the correct

parts. If we worry

about parts that

speed up at the rate

of the driveshaft,

we would be wasting

our efforts.

The purpose of the

examples was to give

you a feel for what

to look at first.

Any weight reduction

is good for

horsepower to weight

ratio, but some

weight reduction has

a bigger payback.

Things that change

speed often, change

speed rapidly,

and/or are heavy at

a large distance out

from the

center...make the

most difference.

Look there first.

The last "things" to

worry about are

small diameter

"things" that change

speed a smaller

amount, change speed

over a longer time,

and change speed

less often. They

will have much less

stored energy. If we

want to reduce

rotating mass we

should look at the

heaviest things that

speed up and slow

down most often,

spin the fastest,

and are large in

diameter with most

of the weight at the

outside edge.

Why do things work

this way?

First we have to

understand what

power and energy

are,

and what rotating

mass does with that

power or energy.

Contrary to popular

belief, rotating

mass does not

consume energy. A

rotating (or moving)

mass stores

energy. This effect

is very much the

same as pouring

energy in a bucket,

much like

charging a capacitor

in an electronics

circuit. Virtually

all of the stored

energy, except for

that lost by

conversion to heat,

is still there and

available to do work

at some time in the

future. That future

where energy is

returned might be

milliseconds later

and help us out, or

it could be some

considerable time

later and waste

energy. This is why

time is very

important.

One example of

useful energy

storage is the

flywheel and

crankshaft of a car.

The force on the

crankshaft is in

pulses. A common

four cycle V8 has four power

cycles per

crankshaft

revolution, and there

are 100 turns of the

crank per second.

At 6000 RPM an

8-cylinder 4-cycle

has 400 power pulses

per second. The flywheel (along

with the harmonic

dampener and weight

of the rotating assembly)

smoothes these pulses

out by storing and

releasing the pulsed energy

from the explosions

in the cylinders.

The result is a

smooth rotation that

will not tear gears

up, vibrate the car, or

beat on

bearings.

We should always

remember rotation,

or movement of a

mass, does not

actually destroy

energy. If it did,

the earth would have

stopped spinning

millions of years

ago! The key to

understanding how

weight changes

affect performance

is to understand

some very simple

basic energy flow in

the system.

Definitions:

Energy

Energy is

the

capacity

of a

physical

system to

perform

work.

Energy

exists in

many forms

like heat,

mechanical,

electrical,

and

others.

According

to the law

of

conservation

of energy,

the total

energy of

a system

remains

constant.

Energy may

be

transformed

into

another

form, but

it is

constant

within a

system.

For

example,

we all

know two

pool balls

eventually

come to

rest after

colliding.

They stop

moving

only

because

the

applied

energy

(from

moving the

cue stick)

is

eventually

converted

to heat

(from

friction

with air

and the

table) and

sound

(which is

not very

much of

the energy

loss).

The ball

movement

along the

table's

felt

surface

and

through

the air

transfers

energy

outside

the two

moving

balls to

the air

and

environment

around the

table and

into the

table

itself.

The

temperature

of the

table and

air rises

ever so

slightly,

because

the

applied

energy

moves

outside

the system

we "see"!

Since the

heat

energy is

spread all

around in

a very

large

area, we

don't

notice the

temperature

rise. We

just

notice the

balls

quickly

quit

moving.

Another

example is

our car's

brakes.

The energy

stored in

the moving

weight of

the car is

converted

to heat by

friction

of brake

pads

rubbing

against

metal

rotors

attached

to the

rotating

wheels.

This

converts

stored

energy

(the

engine put

into the

weight of

the

vehicle)

into heat,

and the

heat

(containing

all of

that

energy)

radiates

out into

the air.

Most of

what we

actually

do in a

car is

move heat

around.

Newton's first law

A mass continues

in its state of

rest, or continues

uniform motion in

a straight line,

unless it is

compelled to

change that state

by forces

impressed upon it.

Old guys like

Newton sure had a

lot of time on

their hands to

think about simple

things, but they

got it right. A

rocket coasting

through outer

space is a good

example. It will

go on forever in a

straight line

unless it hits

something, or

unless gravity or

some other force

pulls it in a new

direction.

The earth

wants to

move in a straight

line, except

gravitational

attraction to the

sun bends its path

constantly.

A bullet

reacts the same

way, except

friction with air

and gravity

changes the

direction and

speed gradually

over distance.

Newton's second

law

The acceleration

produced by a

particular force

acting on a body

is directly

proportional to

the magnitude of

the force and

inversely

proportional to

the mass of the

body.

We push harder

and/or longer, and

something moves

faster. If it is

heavier, we need

to push longer or

harder (or both)

to obtain the same

speed. It takes

more energy to

accelerate a

heavier object to

the same speed as

we might move a

lighter object to

that same speed.

We can either

apply more force

or apply the same

force over a

longer time to

make something

move faster. It is

all about TIME

times the POWER, or the amount of TIME an amount of POWER is

applied. This is

why those big

showoffs can

eventually move a

large boat, a

railroad car, or

an airplane. All

it takes is low

friction and

enough time and

someone who can't

move a Volkswagen

with two flat

tires can roll a

10-ton railroad

car.

Acceleration,

Energy, and Power

Acceleration,

by definition, is a

change in direction

or speed. If we slow

something down it is

acceleration, just

in a negative

direction. If we

turn a vehicle or

any other mass in a

new direction, it is

really acceleration

at a new angle or in

a new direction.

This is why we can

compare or define

braking and

cornering in G-force

(g's), just as we do

with "taking off"

acceleration.

We apply force (and

this means we apply

energy) over time (force applied over time is power) to

accelerate an

object. If we want

to spin a top, we

apply force

off-center from the

axis and at right

angles to the axis.

The top stores the

energy we apply, and

continues to rotate.

Over time the stored

force is converted

to heat from

friction and the top

gradually slows

until it finally

stops.

Force is pressure or

energy. The product

of the time we

apply the force

and the amount of

force is the

power. Power over

time is a very

useful thing to us because it means we can do work with it. Power alone, without

time it is applied,

is not not so useful. Let me give

some examples:

"Watts" are a

measure of power,

much like

horsepower. "Watts"

alone are not

speed, because a

watt does not

include a defined application time. A watt

is only power level, or work level, of energy over an undefined time.

If we include one

hour's time we would

have a watt-hour.

Kilowatt-hours,

watt-seconds,

watt-hours, and

other combinations

of power level and

time define

electrical energy or

work. This is why we

billed for

kilowatt-hours at

our homes! If we

were billed for

plain old "watts",

it would not tell

anyone how much

"work" we bought.

Watts are a true

scalar (single

dimension) measure of ability to do work,

just as horsepower

is. Both indicate a

force or the ability

to do work, but both

lack any inclusion

of work time, so we have

no idea how much

work was done, or

could be done.

Horsepower is a

function of RPM and

torque, just like

watts are volts

times amperes.

Horsepower is an

ability to do useful work,

but doing actual

work requires

time. Torque is

pressure, and since

it does not include

speed it is not a

very useful measure

of system power or

the ability to

accelerate or move

weight. Despite what

we hear,

crankshaft

torque is not

directly related to

moving something off

the line or pulling

a heavy load. Up at

the engine, it is

really all about

horsepower. The

horsepower (torque

at a certain RPM) is

eventually converted

through gears and

other mechanical

devices to a new

torque value at a

different RPM.

Eventually all we

care about is the

rotational pressure

on the contact patch

of our tires that

thrusts our car

forward. A 800 lb/ft

torque at 2000 RPM

engine does not

accelerate a vehicle

as well as a 400

lb/ft engine at 5000

RPM, because

horsepower is a

product of torque

and RPM. The higher

RPM engine can be

geared to provide

more forward

pressure at the

wheels. The

higher RPM engine, with less torque, has

more horsepower.

If you notice, ET

calculators don't

ask for torque. This

is because torque

does not quantify

the ability to do

work. ET calculators

ask for horsepower,

because horsepower

clearly defines an

ability to do work.

Joules are another

common measure of

ability to do work. A joule

includes both time

and force

(pressure). A single

joule is one

watt-second, or the

equivalent of one

watt applied for one

second. A single

joule could be 10

watts applied for

1/10th of a second

(10*1/10 = 1), the

product of time and

force only has to be

ONE watt-second to

make one joule. If

we applied TWO watts

for 1/2 second, we

have the same work.

Two watts for 1/2

second is one joule

(2*1/2=1).

Horsepower can also

be stated in

kilowatts. One

horsepower is

approximately 0.7457

kilowatts, or 745.7

watts (the exact

value is

0.745699872

kilowatts).

This means 746 watts

for one second is

746 joules and that

is one

horsepower-second!

One kilowatt is

1.341 horsepower.

Many European

engines are rated in

kilowatts instead of

horsepower, you've

probably seen that.

A 300-horsepower

engine would be

about 223.7

kilowatts. Your

house probably

consumes between 2

to 5 kilowatts of

average power,

depending on how

large it is and how

you heat or cool.

This is somewhere

between 2-1/2 to 7

horsepower of

average power. Think

of what would happen

to the power grid if

we converted all our

cars and trucks,

like the Greenies

want, to run on

electricity! We

would run out of

electricity very

quickly.

How many joules are

in 1492 watts when

applied for 1/2

second? 1/2 times

1492 or 746 joules!

746 joules is one

horsepower-second.

We could rate our

engines in joules if

we needed to include

both power and time.

Horsepower and

Acceleration

We know horsepower

alone is not a

measure of useful work results,

we must know the

time a certain

horsepower is

applied (or removed)

to know how it

affects

acceleration.

Fortunately there

are horsepower

calculators that

predict ET for a

given power. These

calculators work

because they know

the distance, they

know the applied

horsepower (they

assume it is

constant), and from

that they can

calculate speed and

elapsed time. They

do this because they

assume the power is

applied constantly

and they calculate

the speed change

over time. From the

speed and time, they

get the distance.

When they see 1/4

mile (or 1/8th mile)

they stop

calculating and

display the speed

and the time taken

to reach that speed

and distance.

Now here is an

interesting thing.

It takes a certain

number of

horsepower-seconds

(certain energy

applied) to reach a

certain speed for a

given weight. If we

make the vehicle

twice as heavy, it

takes twice as many

horsepower-seconds

(twice as much

energy) to go the

very same speed.

For example, go to

this link:

http://www.race-cars.net/calculators/et_calculator.html

Now let's apply 100

HP to go 1/4 mile in

a 1000 pound

vehicle. We went

108.6 MPH in 12.55

seconds. Now let's

say we have a 2000

pound car. To have

the same speed and

time, we have to

also double the

applied force. If we

apply 200 HP in our

2000 pound car we

have exactly the

same ET and MPH! Now

we know why

insurance companies,

in the late 60's,

often limited

insurance to a car

with 10:1 weight to

horsepower ratio or

more. They didn't

care if it was a

4,400 pound Super

Bee Dodge with a 425

HP hemi or a 315 HP

3200 pound Hurst

Rambler Scrambler,

the insurance

companies wanted

weight to power over

10:1 ratio or you

could not buy

insurance. 10:1

weight-horsepower is

at very best a 108.6

MPH at 12.55 seconds

car! My American

Motors 10:1

Weight-HP Hurst S/C

Rambler, as a documented fact,

set a new national

ET record of 12.54

seconds in the 1/4

mile back around

1970.

Rotating Mass

Let's say we want to

change the drive

shaft rotating mass

to improve power

available to the

rear wheels. We all

know most of the

weight in a

driveshaft is at the

outer edge. It is a

hollow tube. Let's

say the original

shaft weighed 30

pounds, and we want

to change it to a 15

pound aluminum

shaft. The drive

shaft is 3.5 inches

in diameter.

We can go to another

calculator to find

the joules stored in

the driveshaft! When

we know the joules,

we know the

horsepower-seconds

sapped from moving

the car. Let's say

the engine peaks at

6000 RPM at the end

of the 1/4 mile, and

that took 13

seconds.

Go to this

calculator:

http://www.botlanta.org/converters/dale-calc/flywheel.html

The original

driveshaft weighed

30 pounds and we had

to spin it to 6000

RPM. If we input

that, we see it

consumed (and

stored) 5310 joules.

480 ounces in a 3.5

inch diameter RING

(hollow center) and

6000 RPM.

That is 5310/746 =

7.12

horsepower-seconds

to spin the shaft to

6000. Since the

time was 13 seconds,

the shaft soaked up

0.548 horsepower

distributed over

that 13 seconds.

Now we change to the

aluminum shaft.

Everything is the

same except the

weight, it is now 15

pounds or 240

ounces. Using that

flywheel calculator

we find we used 2655

joules. This is

2655/746 = 3.56

horsepower-seconds.

Over 13 seconds, we

"stored" .274

horsepower. The net

gain in available

energy over 13

seconds was about

1/4 horsepower.

Here is the real

rule of how this

works....

If we are spinning

up a very large

diameter mass, or a

very heavy mass, and

we do it rapidly, we

sacrifice a lot of

available power. If

we are spinning up a

very small diameter

mass, especially

over a longer period

of time, we give up

less power at any

instant.

The change from an

aluminum flywheel to

a steel flywheel is

much more pronounced

than the change of

the same weight in a

driveshaft because

the aluminum wheel

is much larger in

diameter. We also

speed and slow the

flywheel as we

accelerate and

shift, instead of

smoothly spinning

the thing up like a

driveshaft.

The truth is for

drag racing, unless

we have a God-awful

fast car or a road

race car where we

have to instantly

change power, an

aluminum wheel

barely makes a

perceptible change

over a steel

flywheel. The

aluminum wheel can

actually be slower

in a drag car,

because the applied

power is not as

smooth. It is harder

to get a light

aluminum flywheel

out of the hole, and

that can easily

offset any small

"available power"

change.

Summary

This is an

approximation

designed to give you

a reasonable feel

for how a change in

rotating mass

affects

acceleration. We can

see the power

extracted to spin a

weight up is not

very much if we do

not spin it up too

quickly, or if what

we spin is not very

heavy and/or very

large in diameter.

The "feeling" most

people cling to (and

parrot) is that

"heavier rotating

mass kills

acceleration". This

is generally not

true at all for big heavy cars, although it can be true. Most

things we fret about

make no appreciable

difference in the

grand scheme of

things. I would

never bother

changing from steel

to an aluminum

driveshaft in my

car, because my car

takes 11 seconds to

go 1/4 mile. The car

weighs 3000 pounds,

and this means I

might save 20 pounds

of weight and 1/2

horsepower lost to

spinning that weight

over the length of

the track. $400 is

not a good

investment at all

for 1/2 horsepower

over the length of

the track, or the

extra 1/2 horsepower

applied for 11

seconds I have to

extract at the end

and convert back to

heat with my brakes.

I don't really have

to worry about how

fast things spin up

at this point. I

don't care if the

crank is 12 pounds

lighter out of 50

pounds. I don't care

if the driveshaft is

15 pounds lighter

out of 30 pounds! Right now

that $400 to $1000

would go a lot

further if it made

20 more engine

horsepower, or

removed 60 pounds of

static weight. When

I start running out

of easy power, then

I will spend money

making expensive

things lighter. The

big problem right

now is traction, so

right now I want to

smooth the power

out. The last thing

I need is to make

the car more

critical for launch

RPM by using a

lighter flywheel or

shock the tires more

by using a lighter

driveshaft. The

first major weight

reduction will be

the front K members,

because that would

remove weight from

the front and

effectively add a

larger percentage of

weight to the rear

wheels! The last

weight reduction

for my car will be an aluminum

flywheel or

driveshaft.

|